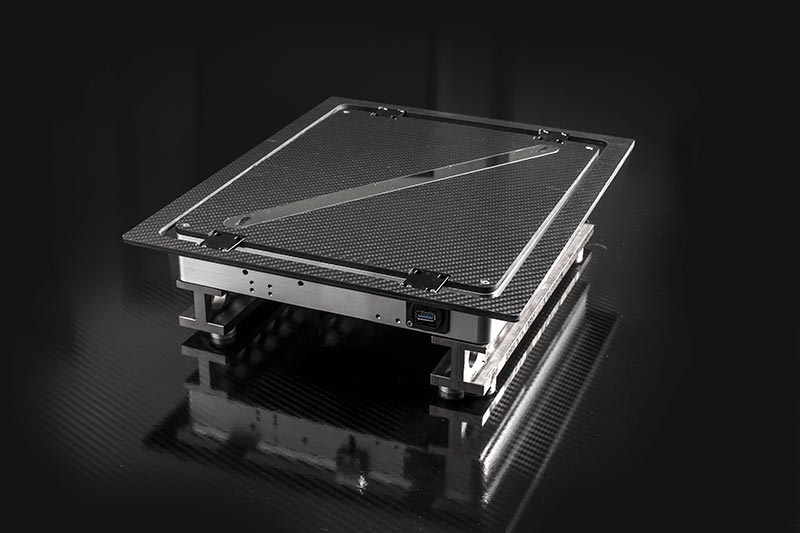

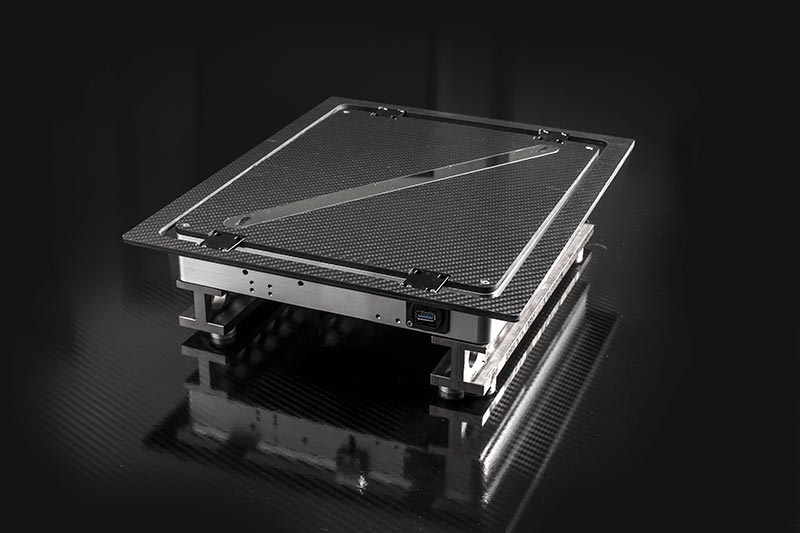

CmPrint

Overview:

Applications:

Mastering Precision in SMT Solder Paste Printing

CeTaQ’s CmPrint systems, comprising the CmPrint 2.0 Basic and CmPrint 2.0 Expert versions, are state-of-the-art measuring systems designed to revolutionize solder paste printing in Surface Mount Technology (SMT) production. These systems provide invaluable insights into the printing process, significantly influencing the quality of subsequent manufacturing steps.

CmPrint 2.0 Basic

The Foundation of Accurate SMT Printing

CmPrint 2.0 Basic is tailored for SMT manufacturers seeking a fundamental yet powerful tool to enhance the accuracy and consistency of their printing processes. It serves as an essential device for optimizing print force in the initial step of SMT production.

Key Features:

- Precise Measurement: CmPrint 2.0 Basic focuses on crucial print force metrics of the solder paste printing process, ensuring the fundamental aspects of print force are accurately set and consistently within desired parameters.

- Quality Influence: As solder paste printing is a critical first step in SMT production, the quality assurance provided by CmPrint 2.0 Basic has a decisive impact on overall product quality.

- Ease of Use: Designed with user-friendliness in mind, it allows operators to quickly adapt and optimize the printing process.

Applications

- Primarily used in machines where fundamental, reliable print force settings are paramount.

- Suitable for manufacturers who require a straightforward, efficient approach to printing quality control.

CmPrint 2.0 Expert

Advanced Dynamics in SMT Printing Analysis

A highly advanced version of the Basic system, the CmPrint 2.0 Expert investigates accuracy, stability, and print forces simultaneously during the printing process. This dynamic analysis is conducted over the entire squeegee stroke, providing a comprehensive view of the printing operation.

Key Features:

- Dynamic Measurement: Without relying on print mediums, CmPrint 2.0 Expert dynamically measures offsets in x, y, and theta directions, along with repeatability and force applied over the printing area.

- Complete Diagnostics: Delivers a full diagnosis of machine accuracy and force, covering the most relevant characteristics on any equipment type and brand.

- Decision-Making Aid: The insights gained from CmPrint 2.0 Expert facilitate planning for new products, technology adoption, and investment decisions.

Applications:

- Ideal for advanced SMT production facilities where precision and detailed analysis of the printing process are crucial.

- Essential for maintenance, repair, or optimization measures, and critical in quality audits due to its comprehensive measurement capabilities.

Impact on SMT Manufacturing:

- Quality Enhancement: Both Basic and Expert systems ensure that the solder paste printing process, a critical first step in SMT production, meets the highest quality standards.

- Process Optimization: Through detailed analysis, CmPrint systems aid in fine-tuning stroke dependent offsets in the printing process, leading to enhanced accuracy and reduced errors.

- Innovation and Development: Insights from CmPrint measurements contribute to CeTaQ’s continuous improvement and future advancements in SMT technology.

Establishing Foundational Accuracy

CeTaQ’s CmPrint systems, with the Basic and Expert versions, provide an unparalleled solution for ensuring precision and quality in SMT solder paste printing. Whether it’s establishing fundamental accuracy with the Basic system or delving into advanced dynamics with the Expert system, CmPrint stands as an essential tool in the arsenal of SMT manufacturing excellence.