Dispensing

Overview:

Dispensing Validation Services

Precision in Every Dab and Drop

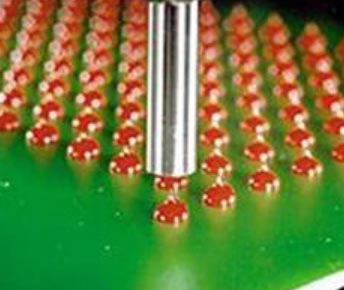

In the meticulous world of Surface Mount Technology (SMT), the accuracy of dispensing processes like adhesive and sealant application plays a crucial role. CeTaQ Americas specializes in providing precision dispensing validation services, ensuring that these vital materials are applied accurately and consistently, which is indispensable for complex SMT processes.

Overview of Dispensing Validation Services

CeTaQ Americas employs cutting-edge inspection technologies to meticulously assess and validate the precision in dispensing processes. This service is designed to ensure that adhesives, sealants, and other crucial materials are applied with utmost accuracy, essential for the integrity and functionality of SMT assemblies. You’ll be confident in our advanced inspection methodology for precise material applications.

Key Aspects of Dispensing Inspection

- Accuracy and Consistency Checks: Our services focus on verifying the X,Y position, and diameter of materials dispensed onto circuit boards or components, crucial for high-quality assembly.

- Process Optimization: We identify any variances from optimal dispensing patterns and provide tailored recommendations to improve the dispensing accuracy.

- Validation and Reporting: Post-inspection, we deliver a comprehensive report validating the improvements and consistency achieved in the dispensing process.

Impact of Precision Dispensing on SMT Manufacturing

- Enhancing Assembly Quality: Accurate dispensing is vital for ensuring the structural integrity and electrical functionality of SMT assemblies. Our inspection services play a pivotal role in maintaining high assembly standards.

- Reduction of Defects and Rework: Precise dispensing minimizes the likelihood of defects in assembled products, reducing the need for costly reworks and material wastage, thus optimizing the manufacturing process.

- Adapting to Complex Assembly Needs: Given the evolving complexity of SMT processes, our dispensing inspection services are adaptable to a wide range of materials and dispensing patterns, catering to the specific needs of advanced manufacturing technologies.

Tailored Validation Solutions

Recognizing that each SMT line has unique challenges, CeTaQ Americas customizes its validation services to meet the specific requirements of different manufacturing setups.

Commitment to Manufacturing Excellence

At CeTaQ Americas, our goal is to empower SMT manufacturers with the tools and knowledge needed to achieve excellence in their processes, ensuring every aspect of production meets the highest quality standards.

Experience and Expertise in Dispensing Inspection

State-of-the-Art Inspection Techniques: Our team of experts utilizes the latest inspection technologies and methodologies, ensuring that our clients receive the most advanced and accurate service.

CeTaQ Americas’ Dispensing Validation Services are a cornerstone in the pursuit of perfection in SMT assembly processes. By ensuring precise and consistent application of essential materials, we help manufacturers enhance the quality, efficiency, and reliability of their products. Trust CeTaQ Americas to bring precision and expertise to every aspect of your SMT dispensing process.